| |

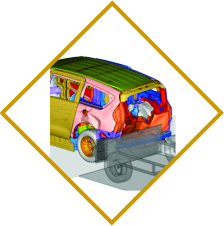

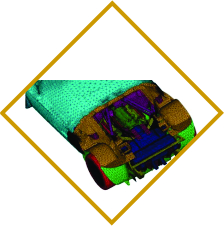

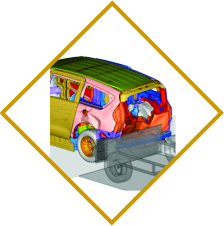

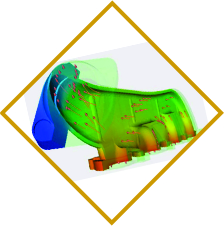

CRASHWORTHINESS |

| |

-

Industry Standard Crash Test Simulations

-

Occupant Safety and Pedestrian Protection

-

Aluminum, High Strength Steel and Composite Simulation

-

Validation against test data

-

Design directions to ensure adequate safety of hybrid vehicles

|

| |

|

Full Vehicle |

| |

|

-

Full Frontal Impact (FMVSS 208, NCAP)

-

Offset Deformable Barrier Impact (IIHS, ECE 94)

-

Side Impact (FMVSS 214, SINCAP, ECE 95), Side Pole

-

Rear Impact (FMVSS 301, ECE 32)

-

Roof Crush (FMVSS 216)

-

Compatibility of Vehicles

|

| |

|

Bumper System |

| |

|

-

Danner/Thatcham

-

Low Velocity Impacts

|

| |

|

Door System |

| |

|

|

| |

|

Seat Systems |

| |

|

-

Belt Pull (ECE14/FMVSS 207/210)

-

Child Restraint Anchorage (FMVSS 225/ECE44)

-

Front and Rear Impacts with Dummies

-

Luggage Retention

|

| |

|

Instrument Panel (IP) |

| |

|

- Knee Bolster

- Front and Side Impact

|

| |

|

Interior Trim |

| |

|

|

| |

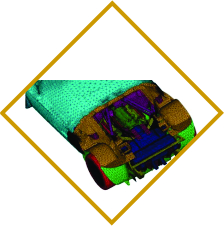

NOISE, VIBRATION AND HARSHNESS (NVH) |

| |

-

Modal Analysis

-

Frequency Response Analysis

-

Random Response Analysis

-

Point Mobility Analysis

-

Four-poster test correlation

-

Dynamic stiffness of powertrain mounts

-

Optimizing mount and bushing stiffness rate

-

Design Sensitivity Analysis

|

| |

|

Body-In-White (BIW) |

| |

|

-

Sheet Metal Only

-

Trimmed BIW

-

Normal Mode

-

Frequency Response

-

Point Mobility

|

| |

|

Closures |

| |

|

-

Doors, Hoods, Lift Gates

-

Sunroof Assembly

-

Normal Mode Analysis

|

| |

|

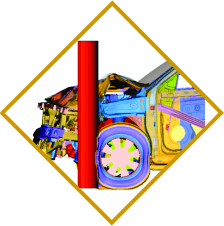

Chassis and Cradle Frame |

| |

|

|

| |

|

Instrument Panel and Console Structure |

| |

|

- Steel, Magnesium, All-Plastic Beams

- NVH with and without Body

- Random Vibration- PSD Input

|

| |

|

Seat Systems |

| |

|

- Normal Mode Analysis

- Test Correlation

- Design Sensitivity Analysis

|

| |

|

Power Train |

| |

|

-

Bending Mode Analysis

-

Transmission- Frequency Response with

Internals

|

| |

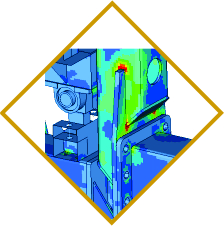

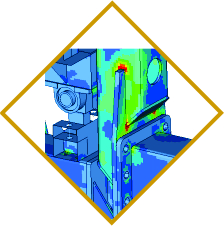

DURABILITY |

| |

-

Linear Stress Analysis

-

Stiffness and Strength Analysis

-

Non-Linear Analysis

-

Hyper Elastic / Highly Non-Linear Analysis

-

Low and High Cycle Fatigue Analysis (Stress based and Strain based)

-

Durability evaluation of different test events like Jounce, Pothole, Braking, Cornering etc.

|

| |

|

Chassis and Cradle Frame |

| |

|

-

Under Road Load from ADAMS

-

Braking, Cornering, Jounce, etc.

-

Inertia Relief Analysis

-

Fatigue Predictions

-

Weld and Weight Optimization

|

| |

|

Suspension Components |

| |

|

-

Knuckle, Control Arms, etc.

-

Hex and Tet Models

-

Multiple Load Cases

-

Wheel- Durability and Impact

-

Weight Optimization

|

| |

|

BIW |

| |

|

|

| |

|

Closures |

| |

|

-

Doors, Hoods, Lift Gates, Tail Gates

-

Rigidity- Torsional, Vertical, etc.

-

Over Check and Belt Squeeze

-

Dent and Sag Set

-

Slam Fatigue

|

| |

|

Seat Systems |

| |

|

|

| |

|

Power Train |

| |

|

-

Engine Block & Cylinder- Bore Distortion

under Thermal & Bolt Loads

-

Exhaust Manifold- Heat Transfer, Thermal

Stress

-

Transmission and Transfer Cases- Bearing

Loads, Sealing

|

| |

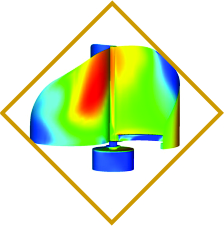

OPTIMIZATION |

| |

-

Topology, Topography and Topometry

-

Design of Experiments

-

Design Sensitivity Analysis

-

Response Surface

-

Multi-Disciplinary Optimization (MDO)

|

| |

MULTIBODY DYNAMICS (MBD) |

| |

-

Rigid and Flexible Multi-Body Systems

-

Mechanism Analysis

-

Vehicle Dynamics and Load Development

-

Tire Modeling and Simulation

|

| |

COMPUTATIONAL FLUID DYNAMICS (CFD) |

| |

|

CFD Expertise |

| |

|

| |

|

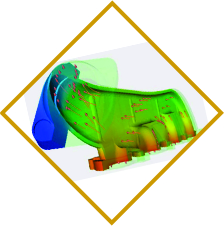

Automotive Headlamp and Tail Lamp |

| |

|

| |

|

CFD Analysis of IC Engine |

| |

-

Predict Heat Transfer Coefficients (HTC) at coolant-wall interface in cylinder head, block, exhaust and intake ports

-

Map HTC at coolant-wall interface to FEA mesh

-

Thermo-mechanical analysis to predict temperatures and stress

-

Bore distortion analysis & Gasket analysis

-

Low cycle and high cycle fatigue analysis

|

| |

|

Vehicle Thermal Management-Coupled CFD & Thermal Analysis |

| |

|

| |

|

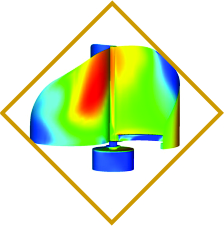

Vertical Axis Wind Turbine |

| |

|

| |

|

FSI – Flow Regulators |

| |

|

| |

PROCESS SIMULATION |

| |

-

Formability- Stamping, Hydro-forming,

Tailor Welded Blank etc

-

Plastics- Mold Flow, Warpage, Weld Line,

Cooling etc.

-

Forging, Casting, Powder Compaction etc.

-

Welding, Heat Treatment etc.

-

Process Optimization

|